Resources Sector Pressure Testing

Available NZ Only

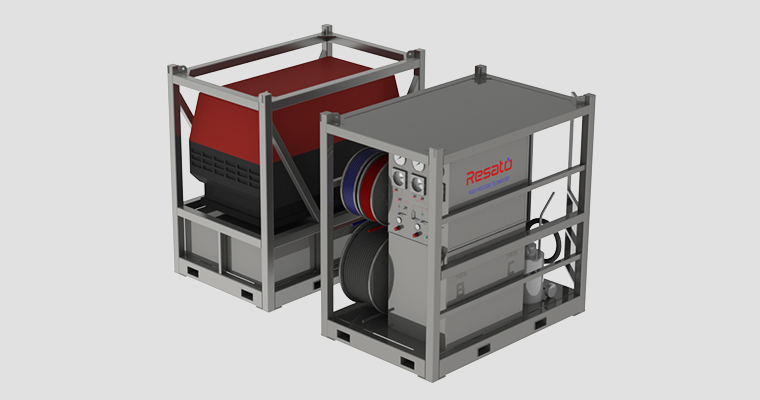

Safety is a key concept in the oil and gas industry. In part, safety can be guaranteed by ensuring that your equipment is safe and reliable. This can only be guaranteed by regular testing. Resato has carefully designed and engineered systems to test different oil and gas components utilising a gas or liquid. Whether looking for robust test systems for your workshop or compact testing equipment to test at different locations, accurate testing by Resato equipment is key.

Field pressure test systems / Pressure test bays / Hose testing equipment / Gas workshop pressure test systems / Hydrostatic workshop pressure test systems

Get In Touch

Industrial – Pressure Testing

Available NZ Only

The industrial sector generally processes raw materials into a finished product or component. It is essential in today's markets to produce a high-quality product. By working with safe and reliable machines, you ensure that the end product produced meets the set requirements. These two required characteristics of your machines can only be guaranteed by rigorous and programmed testing. Resato can provide the test equipment and solution for your business. Our systems enable you to test both machine components, the end product, and the component parts within.

Component validation systems / Leak testing systems

Get In Touch

Automotive Industry Testing

Available NZ Only

Resato's experience with Hydrogen Testing in the Automotive Industry With the technology rise of Fuel Cell Electric Vehicles (FCEVs) in the automotive industry, pressure tests are performed on hydrogen tanks and components to ensure safe operation.

Various vehicles contain parts that are subject to high pressure. For example, pumps, pressure vessels and pipes. It is important to test these components in order to guarantee their safety and quality. Our hydrostatic systems perform tests with a liquid and our gas systems with gas. The test systems have range of test pressures up to 14,000 bar. Systems can be adapted to ensure it is the most suitable test system for your requirements.

Get In Touch

Hose Testing

Resources Sector – Controls

Available NZ Only

In the oil and gas industry, crude oil and natural gas are extracted. This production is a dangerous process. When a small thing goes wrong it can have major consequences for operators, the drilling rig and the environment. That is why it is important that production is done in a safe, controlled manner. Resato and EHL can support you in this process with various well controlling systems. With more than 30 years of experience in the industry, our experts will advise you on the most suitable device for your purposes.

Get In Touch

Resources – Filling / Injection

Filling covers both the resources and industrial sectors. This application is all about filling or refilling a medium at high pressure. In the oil and gas industry this can be applied to pressurize the needed well-components in various stages of well start-up . In industrial processes, accumulators are refilled with liquids or gases. The media from these accumulators are then used to store energy for a variety of high pressure applications.

Get In Touch

Resources Sector – HP Injection

In addition to producing as much oil as possible from the existing reserves, the aim is to remove the oil from the well as cleanly as possible. Chemical injection can contribute to this. Bringing small amounts of chemicals into the well prevents corrosion and solves blockages. Excessive injection has the opposite effect. Moreover, this is dangerous for the operators. It is therefore relevant to work very precisely. Our injection components and systems provide both safety and accuracy.

Get In Touch

Gas & Liquid Compression

Gas Compression

Liquid Compression