Safe Quality Foods (SQF) Institute standards

How to Meet the SQF Compressed Air Standard

What Is the SQF Air Quality Standard?

Safe Quality Foods (SQF) Institute defines air quality in its SQF Code – 8th Edition, Section 9.5.6.1-2 as Compressed air used in the production process shall be clean and present no risk to food safety; Compressed air used in the production process shall be regularly monitored for purity.

Why Is the Air Quality Standard Important?

Contamination in compressed air systems can come from many sources. Dust particles, hydro-carbons and humidity are collected from the environment and concentrated by the air compressor. Oil aerosols from the compressor lubricant and rust particles from the piping can break free and enter the compressed air stream. If these contaminants are not removed, there can be negative impacts on processing systems, food safety and quality. There are several Good Manufacturing Practices (GMPs) published to ensure superior air quality. One of the most important GMPs relates to adequate point-of-use filtration. Since contaminant enters the air steam at all points in the process, point-of-use filtration ensures that clean, safe air comes in contact with food and food contact areas.

How Can I Meet the SQF Air Quality Standard?

The SQF auditor looks to make sure manufacturers have the proper point- of-use filtration in place to ensure clean, safe air. That means that the air coming in contact with food or food contact surfaces should present no risk to food safety. Using sterile grade air is one of the most effective ways of reducing food safety risk. Every compressed air installation needs to ensure removal of particulate and coalescing contaminants down to a safe level. Donaldson has three filter combinations outlined below that meet the SQF air quality standard. Monitor your compressed air line regularly to ensure integrity of the filtration system. By installing proper compressed air filtration at the point-of-use, you will meet or exceed GFSI, CFR Title 21, and the SQF standard for compressed air.

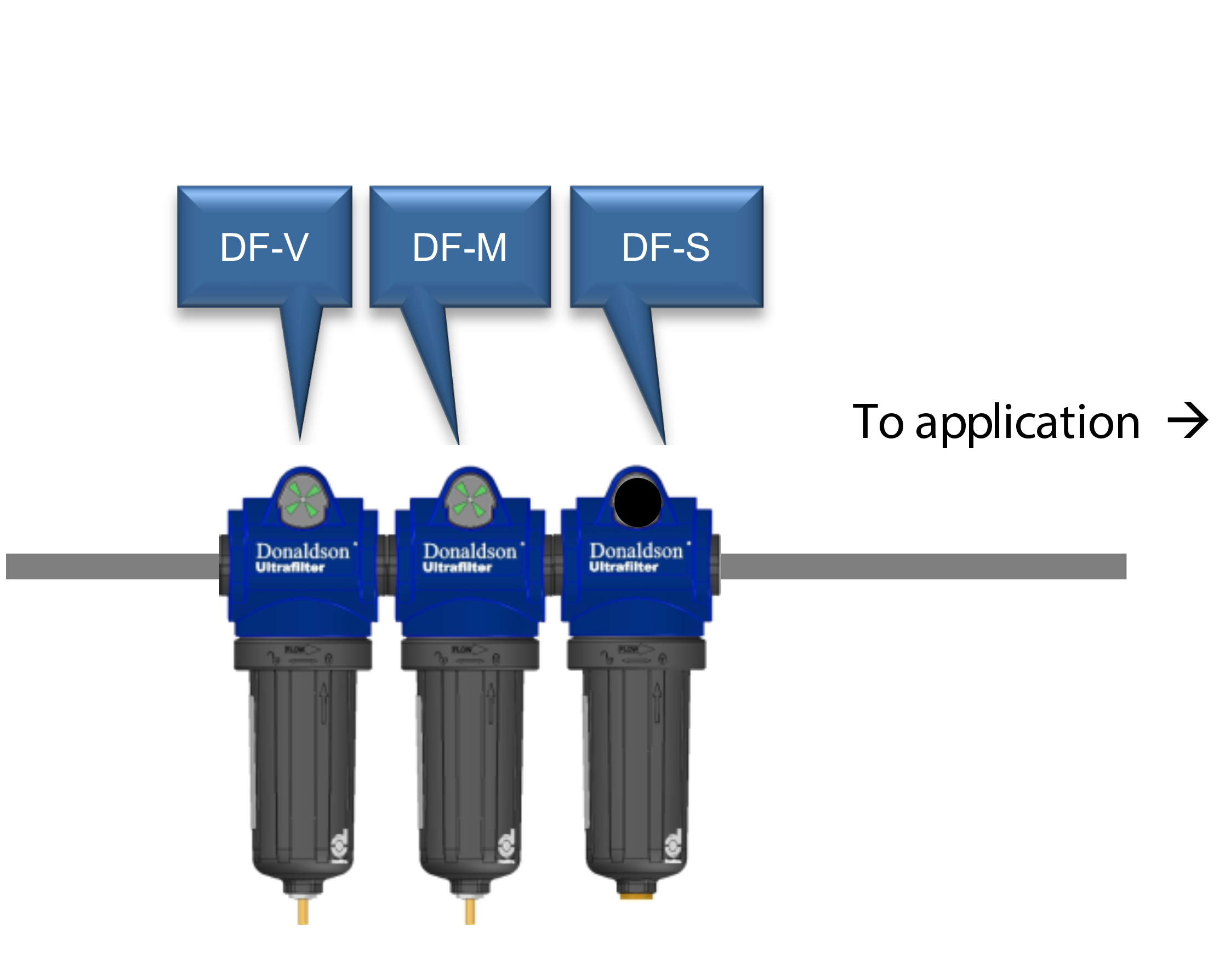

OPTION 1: All Aluminium Housings – use when Steam-In-Place sterilization is not required.

- DF-V Particulate Filter Element (99.9% efficiency at 5 microns)

- Replaced annually or when differential pressure is indicated on the differential pressure gauge.

- DF-M Coalescing Filter Element (99.9999% efficiency at 0.01 microns)

- Replaced annually or when differential pressure is indicated on the differential pressure gauge.

- Lowest pressure drop coalescing element on the market.

- DF-S SQF Final Filter Element (99.99998% efficiency at 0.01 microns)

- Replaced every 3 months.

| Part Description | Capa- city (SCFM) |

Connec-tion (FNPT) | Elements | Dimensions (in.) | Part Number | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Element Size | Stage 1 | Stage 2 | Stage 3 | H | W | D | ||||

| DF 0035 HOUSING COMBINATION |

20 | 1/4 in. | 0035 | V – Coales-cing | M – Coales-cing | S – SQF Final Element | 9.9 | 9.3 | 3.6 | 1C488580-63 |

| DF 0120 HOUSING COMBINATION |

70 | 1/2 in. | 0120 | V – Coales-cing | M – Coales-cing | S – SQF Final Element | 13.4 | 11.7 | 5.8 | 1C488581-63 |

| DF 0210 HOUSING COMBINATION |

123 | 3/4 in. | 0210 | V – Coales-cing | M – Coales-cing | S – SQF Final Element | 15.9 | 15 | 7.9 | 1C488582-63 |

| DF 0320 HOUSING COMBINATION |

188 | 1 in. | 0320 | V – Coales-cing | M – Coales-cing | S – SQF Final Element | 17.4 | 15.9 | 7.9 | 1C488583-63 |

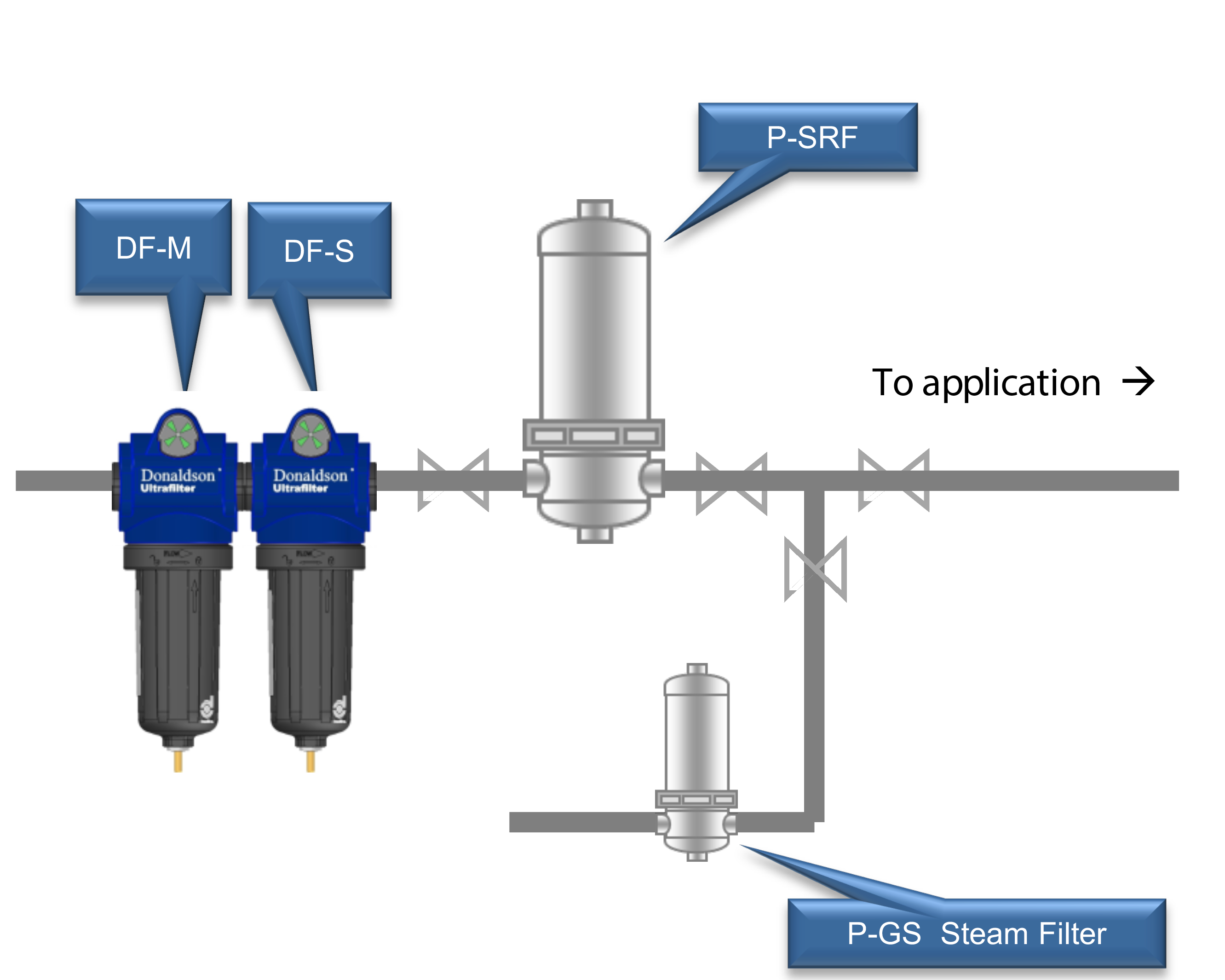

OPTION 2: Hybrid of Aluminium and Stainless Steel Housings – use when Steam-In-Place Sterilization is required.

- DF-M Particulate Filter Element (99.9999% efficiency at 0.01 microns)

- Replaced annually or when differential pressure is indicated on the differential pressure gauge.

- Lowest pressure drop coalescing element on the market.

- DF-S Coalescing Filter Element (99.99998% efficiency at 0.01 microns)

- Replaced annually or when differential pressure is indicated on the differential pressure gauge.

- Lowest pressure drop coalescing element on the market.

- P-SRF SQF Final Filter Element (99.9999998% efficiency at 0.02 microns)

- Replaced every 3 months or after 100 Steam Sterilization Cycles.

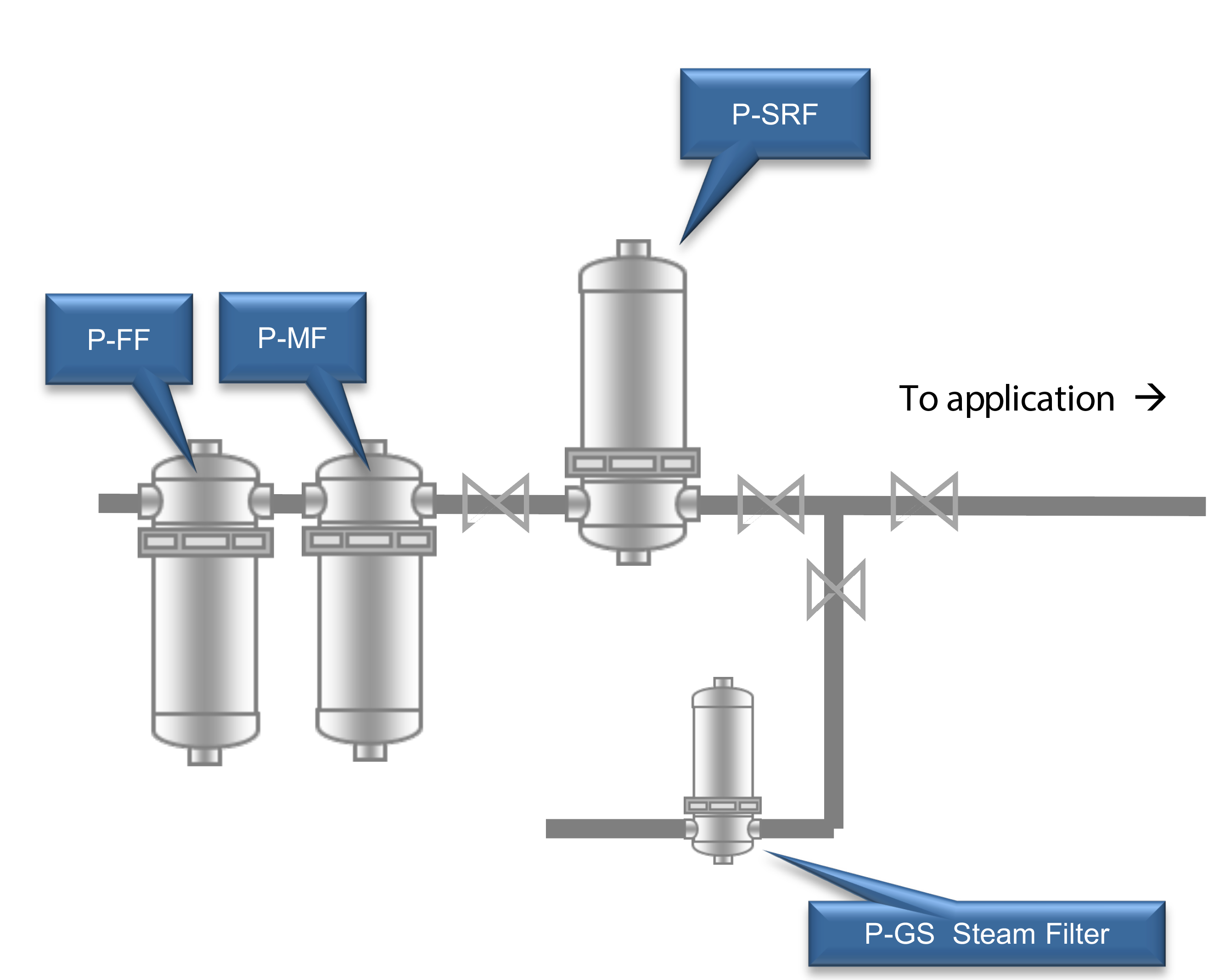

OPTION 3: All Stainless Steel Housings – use when Steam-In-Place sterilization or stainless steel filter housings are required.

- P-FF Particulate Filter Element (99.9999% efficiency at 0.01 μm)

- Replaced annually or when differential pressure is indicated on the differential pressure gauge.

- P-MF Coalescing Filter Element (99.99998% efficiency at 0.01 μm)

- Replaced annually or when differential pressure is indicated on the differential pressure gauge.

- P-SRF SQF Final Filter Element (99.9999998% efficiency at 0.02 μm)

- Replaced every 3 months or after 100 Steam Sterilization Cycles.

About SQF

Consumers are more aware and concerned with food safety than ever before. They expect more from their retailers and food service providers, who in turn expect more from their suppliers. Suppliers must provide verifiable proof that robust food safety control systems have been effectively implemented. As our food supply chain globalized, the demands for global food manufacturing standards grew. SQF was approved by the Global Food Safety Initiative (GFSI) in 2005 to deliver consistent, globally recognized food safety and quality certification programs based on sound scientific principles. Major US retailers began adopting SQF requirements in 2007 which was in turn adopted by global food processors. With the consolidation of standards, food processors can manage their food safety under one quality standard.

To learn more about Donaldson’s filtration solutions for the Food & Beverage industry

Contact your EHL Specialist