|

Industrial Pressure Gauges

General industrial gauges are for use on non corrosive applications where the medium will not attack brass or phosphor bronze. Suitable for use with temperatures up to 60 deg C, for higher temperatures we can offer syphons or gauges with silver brazed components. These gauges are available in nominal diameters of 50, 63, 80, 100, 150, 200,250, 300mm with ranges from vacuum –100-0 kPa up to 100,000 kPa.Standard scales are offered in units of kPa or dual kPa/PSI but also can be offered in bar, mwg, ftwg, inHg, KG/cm2, KN, Ton, Tonne or to your special requirements from coloured sectors, purpose wording, logos and red lines. |

|

|

Liquid Filled Pressure Gauges

Protect against pulsation and vibration with liquid filled gauges. Available in stainless steel cases with brass or 316 stainless steel wetted parts for corrosive applications.

Glycerine is the fill for normal temperature applications and silicone is the fill for higher temperature applications. |

|

|

Low Pressure Gauges

Low pressure gauges operated by a capsule system and only suitable for use on air and some gases. Pressure ranges from -2.5-0 kPa up to 0-60 kpa pressure or vacuum.Offered with stainless steel casing and brass connections for the use on non corrosive applications, but can be offered with stainless steel wetted parts on request. Dial sizes available are 63mm, 100mm and 150mm. |

|

|

Speciality Gauges

At Floyds we are able to offer a manufacture, restoration and repair service to suit old existing machinery.This service applies to pressure and temperature gauges |

|

|

Refrigeration Gauges

This service applies to pressure and temperature gauges, for use on industrial refrigeration equipment and can be offered to suit all refrigeration gases. Supplied with dual scales, inner pressure in black and the outer temperature in red. Can be offered in dry steel cases or stainless steel glycerine filled to protect against pulsation and vibration. Normally supplied in two different mountings, surface mount with a back flange and flush with a 3 hole fixing front flange. Dial sizes 63mm and 100mm |

|

|

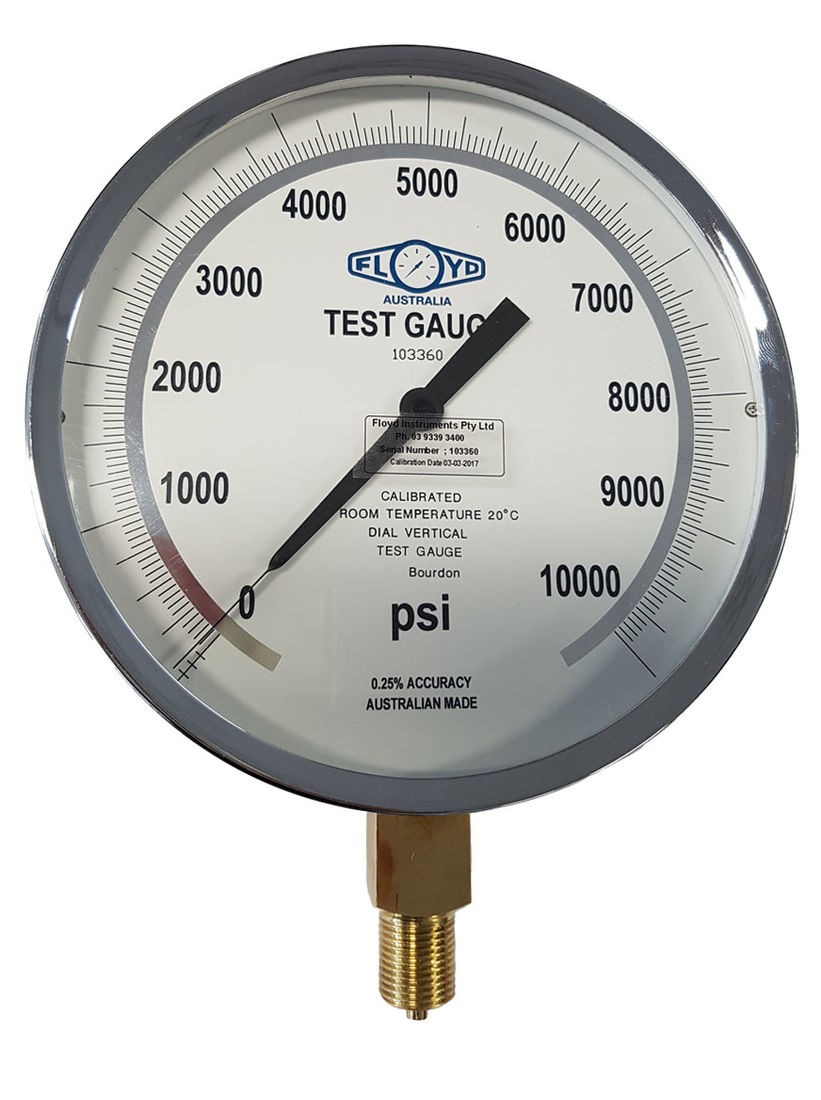

Test Gauge

Precision test gauges manufactured to the highest standard in quality. Used for the testing of industrial gauges or equipment of the same standard. For quality control testing requirements it is not always necessary to use a primary standard such as a dead weight tester, therefore a secondary standard such as a test gauge can be used, being a more convenient and economical method of testing. |

|

|

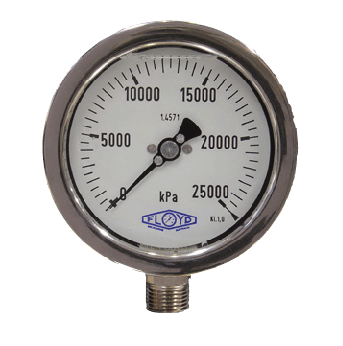

Full Stainless Steel Pressure Gauges

Stainless steel robust construction for corrosive applications where brass is not suitable. Widely used within the oil and chemical industries. |

|

|

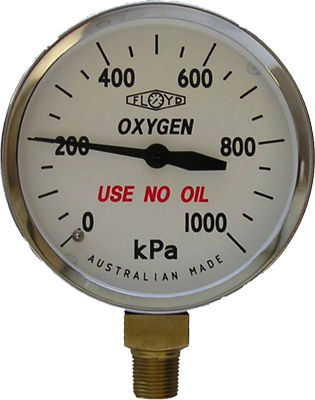

Safety Pattern Pressure Gauges

These gauges are generally used within the gas industry are designed with operator safety in mind in case of a bourdon tube rupture and that no projectiles will blow out from the front of the gauge. Safety pattern construction consists of a front baffle wall, perspex window and a blow out disc in the rear of the case. Dial sizes available are 100mm and 150mm with pressure ranges up to 100,000 kPa. |

|

|

Sanitary Pressure Gauges

Sanitary gauges are specially designed to exceed the demanding safety requirements of the food, dairy, beverage, pharmaceutical, and biotech applications. |

|

|

Chlorine Pressure Gauges

Designed specifically for use on chlorine service, these gauges are fitted with a PTFE lined or PVC wetted parts diaphragm for gauge protection. |

|

|

Differential Pressure Gauges

All stainless steel construction in 100mm and 160mm dial sizes. Differential pressure ranges from 0-25 mBar up to 0-25 Bar with maximum static pressures up to 100 Bar. Can also be offered with electrical contacts and diaphragm seals when the medium contains solids. |

|

|

Digital Pressure Gauges

The 2nd generation XP2i is a very rugged, intrinsically safe, digital pressure gauge with 0.1% of reading accuracy.

|

|

|

Duplex Pressure Gauges

The duplex gauge are also known as a dual pressure gauge, consisting of two independent bourdon tube systems with two independent pointers within the one gauge.

Various uses within the general industry are for reading differential pressures across filters, orifice plates etc. and more commonly on rail transport braking systems. Duplex gauges can also be a big advantage when installed in panels due to the space saving using only one gauge instead of two. Dials can be produced as a single scale, dual or even with two different scale ranges, special markings such as coloured bands, lines or sectors can also be offered.

These gauges are manufactured to an IP54 rating and will withstand most environmental and mechanical shock conditions with their cast brass or aluminium cases but are not suitable for corrosive applications due to the brass and bronze wetted components. |

|

Schaffer Diaphragm Pressure Gauges

Most commonly used as a tank contents gauge due to it being able to operate at low pressures and on liquids. Also used on mediums that contain solids that may block a standard gauge. Dial sizes are 100mm and 150mm with ranges from -2.5-0 kPa up to 0-60 kPa pressure or vacuum |

||

|

Diaphragm Seals

For use on corrosive and non-corrosive applications, where the medium may contain solids or solidify which would cause the normal bourdon tubes to be blocked and unserviceable. Diaphragm seals can be fitted to a vast array of pressure/vacuum gauges.

The normal working temperatures of diaphragm seals is 0-100 degC but can be rated as high as 300 degC when filled with HT silicone oil and the gauge separated from the diaphragm seal using an extended neck or capillary tubing. |

|

|

Sub – Sea

Suitable for use down to depths of 1200 metres of water and in hyperbaric conditions. Dial sizes available are 63mm, 100mm and 150mm with pressure ranges from 0-6 Bar up to 0-1600 Bar. |

|

|

Recorders

Pressure, temperature or a combination of both can be offered with these recorders with an option of a 1, 4, 12, 24 hour or 7 day mechanical clock. Chart sizes available are 166mm, 223mm and 300mm in diameter. Pressure ranges are from -1 to 0 Bar up to 1600 Bar and temperature from -200 Deg C up to 800 Deg C. |

|

|

Syphons

To be used in conjunction with a pressure gauge when the process is steam. The bottom part of the syphon is filled with water which forms a barrier between the gauge and the live steam, thus preventing the gauge from being subjected to too higher temperatures. Available in mild steel or stainless steel with 1/4″, 3/8″, 1/2″ BSP or NPT threads.

|

|

|

Snubber – Pulsation Dampener

Snubbers (Pulsation Dampeners) are used in line with a pressure gauge to suppress line pulsations and keep the pointer steady. They have a combination of a ball check valve arrangement for protection against sudden pressure surges and an adjustable fine thread choke valve to smooth out minor line pulsations. |