AZURA Ocean Technology

AZURA Ocean Technology systems can produce potable water, energy, or both from a single unit whilst contributing zero emissions. Utilising the resource that surrounds us with higher efficiency, 24/7 up time, and without the horizontal impact or land use of wind turbines and solar farms. The AZURA will form part of the supply mix ensuring the flow of energy continues if the sun is not shining or the wind not blowing either from singular units or in arrays for larger requirements.

Read MoreGet In Touch

Hydrogen Refuelling Station – Public (NZ Only)

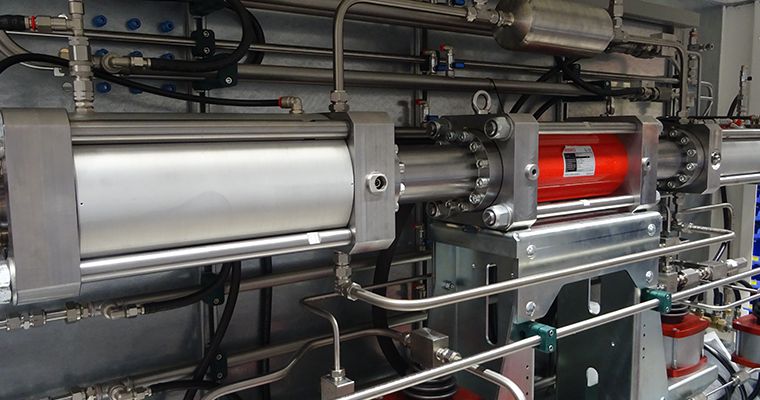

The H2Refuel Full Sized Station (FSS) is designed as public Fast Fill Hydrogen Refuel Stations (HRS) for the developing Hydrogen mobility market. Adapting to the predicted future Hydrogen Mobility refuelling demand, Resato has made his compression technology available by means of large capacity public Hydrogen Refuel station.

Having its origin in high demand 24/7, high flow/high pressure Hydrogen testing applications, refuel station owners benefit in reliability, focus on OPEX and aftersales support. Resato FSS series public refuel stations provide regular petrol refuel experience for Hydrogen vehicles. With a standard capacity of 480 kg/day already available at low supply pressures, the design is in the top range of commercially available HRS worldwide. Sufficient integrated buffering capacity allows three cars back-to-back (empty tank) refuelling.

Read MoreGet In Touch

Hydrogen Refuelling Stations – Fleet (NZ Only)

The H2Refuel Fleet Owner Station (FOS) is designed to provide fleet owners, governments and entrepreneurs with a cost-efficient solution for refuelling FCEVs with hydrogen at 700 bar. The design avoids expensive components such as pressurized hydrogen storage and hydrogen cooling prior to filling. This makes the fleet owner station financially attractive for the development of a hydrogen refueling infrastructure, which requires a relatively low capital investment compared to a public station. The FOS consists of three components: Compression module, Dispenser module and the control console, to ensure safe operation, the electrical components are scanned from the hydrogen holding parts and the Resato – Gas booster technology is integrated in the station to ensure safe refueling of the vehicle at 700 bar.

Read MoreGet In Touch

Hydrogen Testing Solutions

Available NZ Only

Within the hydrogen market a large range of high-pressure components are used. Validation test are performed on hydrogen tanks and components to ensure safe operation. We use our high-pressure knowledge to manufacture hydrogen test equipment. Test equipment specially designed to test different objects, on strength, leakage, deformation with hydrogen or fluids as a medium. Our systems can perform tests according to these standards: ISO 15869, FMVSS 304, GTR No.13, SAE J2579, EC79, R134 and more.

Get In Touch

Hydrogen Production Testing

Available NZ Only

Within the Hydrogen market, components are used that require extensive testing procedures to achieve product validation and are therefore subject to a large variety of test under extreme conditions. We can deliver systems for Hydro testing, Hydro burst testing, Hydro cyclic testing, Hydrogen testing, and more. This is according to EC79 or R134, for small series or fully automated testing as part of customer robotized handling systems.

Get In Touch

Hydrogen Leakage Test

Available NZ Only

Hydrogen testing is a test preformed to determine Hydrogen leakage, the test is performed by filling the object with Hydrogen at a certain pressure and for a certain period of time. We can deliver the needed test equipment to perform this test in a safe and controlled environment. The test can be performed for example following the SAE2601 filling protocol for Hydrogen refueling. Hydrogen recycling can be part of the configuration, to maintain focus on OPEX & green footprint. Test can be in the range of single tests up to cyclic testing as per for example GTR No. 13.

Get In Touch

Hydrogen Cyclic Tests

Available NZ Only

Hydrogen cyclic tests are preformed to simulate the typical life of an object. During the preformed test on a Hydrogen storage tank, the tank Is fast filled like at the Hydrogen refuelling station, for example following the SAE2601 protocol, followed by an emptying phase representing gas consumption. This cycle is repeated several thousand times to simulate the life of the tank. Hydrogen recycling can be part of the configuration, to maintain focus on OPEX & green footprint. During these cycles, various parameters can be monitored, such as temperature and deformation of the tanks as well the possible leakage of hydrogen, to evaluate their long-term performance.

Get In Touch

Hydro Cyclic Tests

Available NZ Only

Hydro cyclic tests are preformed to simulate the typical life of an object. During the preformed test on a Hydrogen storage tank, the tank Is filled with a fluid and pressurized, followed by an emptying phase representing gas consumption. This cycle is repeated several thousand times to simulate the life of the tank. During these cycling, various parameters can be monitored, such as temperature and deformation of the tanks as well the possible leakage, to evaluate their long-term performance.

Get In Touch

Hydrogen Hydro Testing

Hydrostatic testing is a pressure test preformed on objects to determine strength and leakages, with a liquid, usually water. Hydrostatic testing is the most common method for testing. During the Hydro test the object will be filled with water, the object is pressurized to a certain level for a specific amount of time, based on customer or industry requirements. Acceptance of the test is based on the ability of the material under test to hold the specified pressure without deformation of the material or leakage.

Get In Touch

Hydro Burst Test

Available NZ Only

Hydro burst tests are destructive tests and performed to validate the object calculated safety factor. The tests are performed with a fluid, usually water. This test is often performed as a pre-production test to meet safety and quality standards. Often the burst test is preformed periodically on produced parts, for example, 0,5 % of the total batch size is burst tested. With a Hydro burst test the object will be filled with water, the pressure in the object is slowly increased till object burst. Steady pressure build is required to ensure reliable analyzing.

Get In Touch